Asset Integrity Management System

Asset Integrity Management (AIM) is a standard of operating that aims to protect equipment, health, safety, and environment. We define AIM as the minimization of operational risk within a company for maximum business profit. We develop the software on demand to minimize the risk to achieve safety, productivity, reliability and sustainability. We provide software solutions with automation technology to achieve the performance to maximum height. Following are the list of software but not limited, which we develop on demand:-

Cygnus - The Overall Solution

- Cygnus is a software product which is able to manage all integrity analysis like RBI, RCM, IMS, PIMS etc. programs in a single environment.

- It is based on client-server architecture, developed in MS .NET & MS SQL server based technology.

- Centralized database system which can maintain all categories of equipments as listed in the previous slide.

- It is not limited with number of modules, if any new analysis is required, team develop it and can include in the existing software.

- Functionalities are not limited. If any module is required to extend/modify some functionalities, cab be done by development team.

- The software would be functional and to link with any system like Power BI, Tableau for effective visualizations and decision making.

Its Modules

The Cygnus can include but not limited with the following modules:-

- RBI (Risk Based Inspection), Qualitative & Quantitative

- RCM (Reliability Centered Maintenance)

- IMS (Inspection Management System)

- PIMS (Pipeline Integrity Management)

- FFS (Fitness for service)

- RCA (Root Cause Analysis)

- LOPA (Layer of Protection Analysis)

- HazOp (Hazard & Operability)

- Other

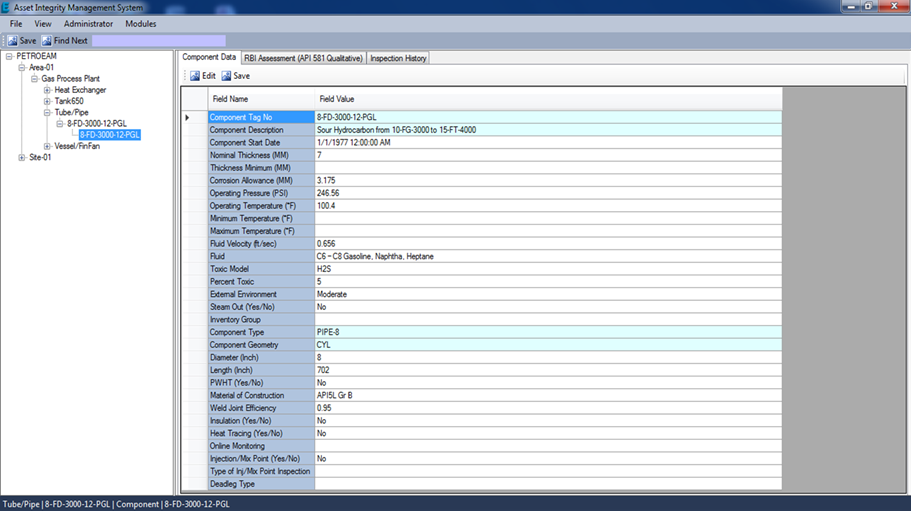

1. RBI Module

The RBI module is based on API 581, qualitative, semi-quantitative, quantitative, however the quantitative module is under development. The qualitative RBI module has following features:-

- Select equipments for RBI analysis from centralized database

- Equipment hierarchy management

- Equipment and component data based on API 581

- Configuration of corrosion circuits

- Identification of damage mechanisms based on API 581

- Probability of Failure (PoF) and Consequence of Failure (CoF)

- Risk calculation and risk matrix

- Inspection interval, inspection date and development of inspection plan

- Inspection (NDT) recording

- Metal loss, corrosion rate, remaining life calculation

- Dynamic reporting features

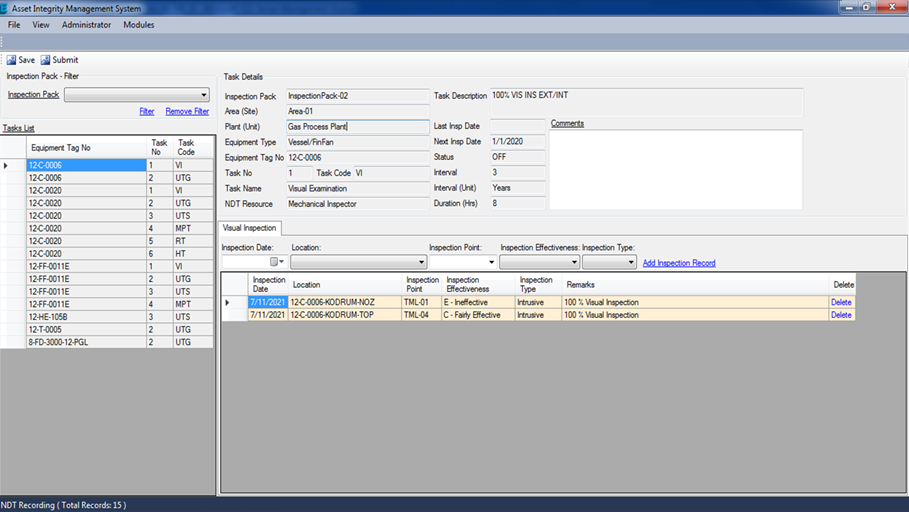

IMS Module

The IMS module has following features:-

- Role based model to manage Inspection integrity

- Development of generic inspection plan

- Attach generic inspection plan to an equipment

- Schedule inspection, inspection pack

- Categorize inspection tasks , notification generation

- Work order generation

- Record inspection, submit for review & approve and flow-chart implementation as per the client.

- Approve inspection

- Calculate inspection interval and assign next inspection date

- Metal loss, corrosion rate, remaining life calculations

- Easy to use and import data, minimizes efforts

- Generate reports

Benefits

- Simple & user friendly

- Cost effective (Integrated modules)

- Reduce maintenance complexity

- All of Facility’ capable IMS (extensible)

- Holistic approach to integrity (flexible & customizable)

- Compatible with Standards & existing methodologies

- Transparent (not a black box)

- Secure & auditable

- Inspection data acquisition capability (track record)

- Rapid access to information (proven cost savings)

- Efficient data handling

- Database interfacing capability (no duplication of data)